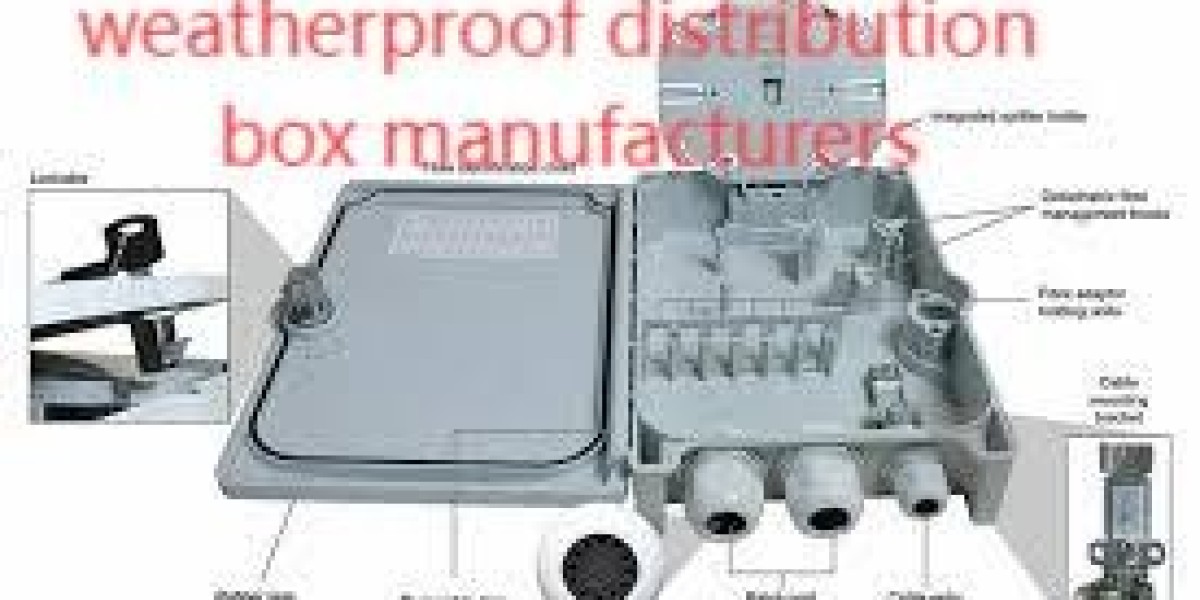

1. Extreme Climate Survival: Beyond Basic Waterproofing

Modern weatherproof distribution boxes must endure hurricanes, sandstorms, and polar freezes. Leading weatherproof distribution box manufacturersnow integrate self-sealing gaskets and AI-driven drainage systems. These innovations prevent ice buildup in Arctic mines and repel saltwater corrosion in coastal solar farms, ensuring reliability where traditional designs fail.

2. Smart Monitoring for Unpredictable Environments

IoT sensors embedded in distribution boxes track real-time humidity, pressure, and temperature fluctuations. For example, flood-prone regions deploy units with hydrostatic pressure alerts, while desert installations use dust-particle counters. Machine learning algorithms predict insulation degradation, cutting maintenance costs by 35% in off-grid energy projects.

3. Materials Engineered for Zero Compromise

Gone are bulky steel enclosures. Aerospace-grade aluminum alloys, graphene-coated polymers, and anti-UV nanocomposites dominate new designs. These materials slash weight by 50% while resisting -40°C to 120°C extremes. In typhoon-hit Southeast Asia, such boxes have reduced storm-related outages by 90%.

4. Modularity for Rapid Disaster Response

Post-disaster power restoration demands speed. Modular weatherproof systems with snap-lock connectors enable field teams to assemble high-capacity distribution nodes in 20 minutes. Deployed in wildfire-stricken California and earthquake zones in Japan, these units support temporary hospitals and communication hubs.

5. Carbon-Neutral Manufacturing for Climate-Conscious Markets

Weatherproof distribution box manufacturers now prioritize circular production. Recycled ocean plastics account for 70% of new enclosures, while solar-powered factories in Scandinavia achieve net-zero emissions. End-of-life units are repurposed into microgrid components, aligning with UN Sustainable Development Goals.

Conclusion As climate volatility reshapes global infrastructure, weatherproof distribution box manufacturers are redefining resilience—merging cutting-edge materials, predictive tech, and eco-conscious practices. Explore advanced solutions at https://www.nante.com/product/.